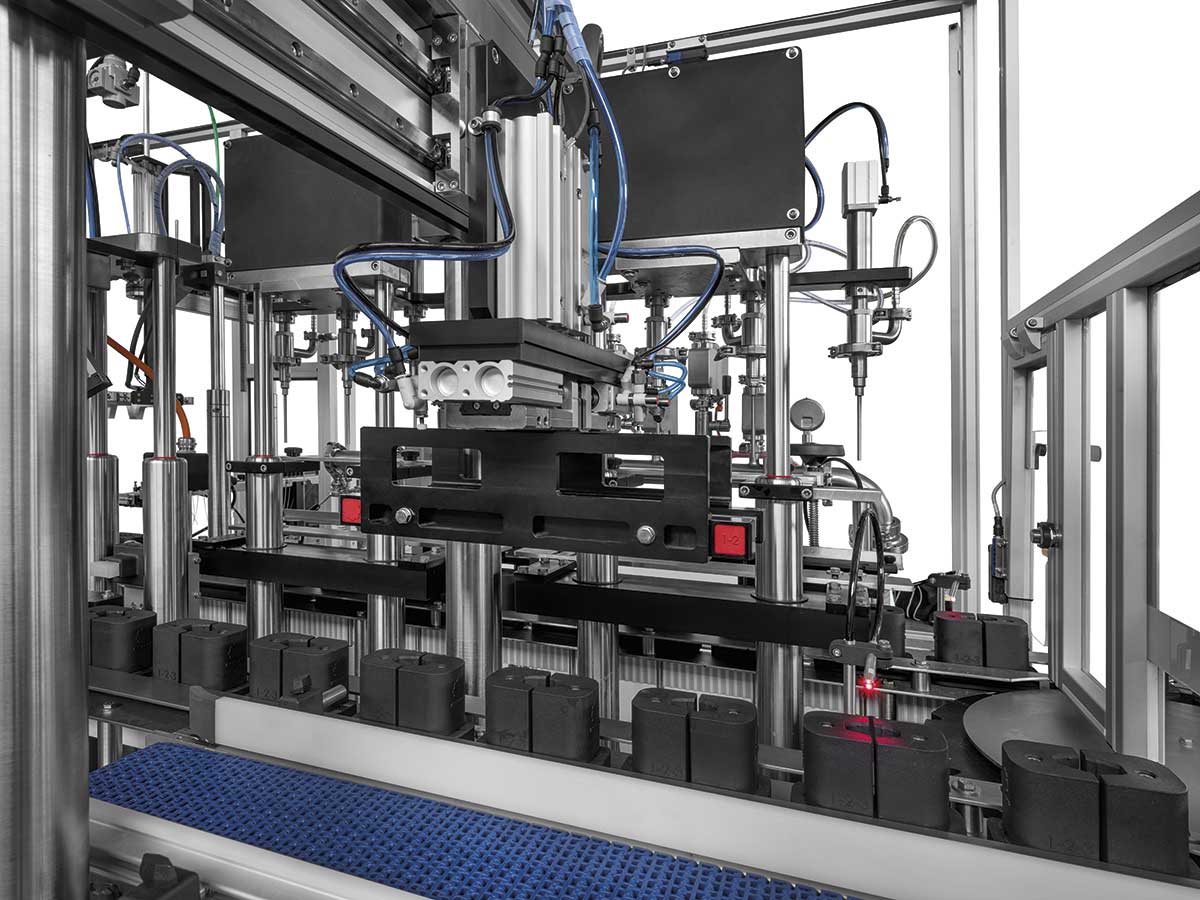

The machines of the RT series have been created as an answer to manufacturers that need a highly flexible machine and to process unstable bottles or bottles with shapes that are difficult to process on a conveyor belt.

RTM model has a filling system using mass flowmeters and an electronic control system for moving needles that gives customers the total control over the management of the volumes to be filled, their speed and power.

RTS model has been created to process products to be dosed by means of systems such as pneumatic pistons, heated hoppers or dosages of special products, filling processes at level, vacuum sealing, etc.

RTP has a piston pump filler to dose high-viscosity products, and if needed, the dosing system can be heated.

The conveying system features pucks on a belt, rather than on conveyor, so that bottles are better stabilised during the filling and closing stages.

The time required to change format is extremely short and the operations, in most of the cases, can be carried out by non-specialised personnel too.