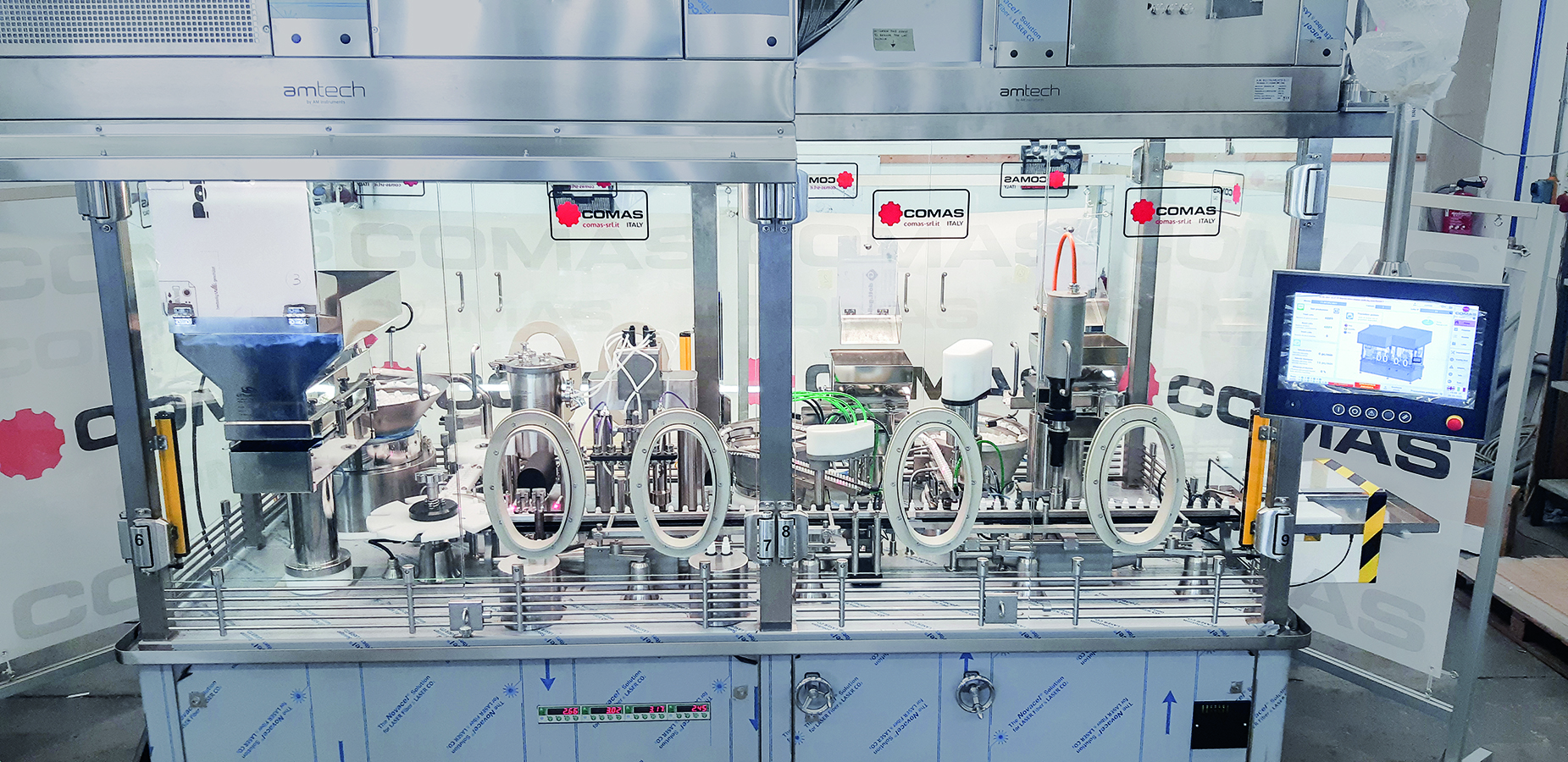

The new RSL model is a versatile, double index machine, designed to fill and close most pharmaceutical containers especially ophthalmic and injectables.

Its special design ensures ideal flexibility and ease of use for both operators and the customer’s maintenance technician. At the same time, the machine has been designed to meet the standards in force in the pharmaceutical industry and to work in sterile rooms for processing injectable products, plus the chance to be equipped with a LAF system and use of gloves. The machine has been built using FDA-approved materials such as stainless steel and anodised aluminium. If the machine needs to be configured to work in sterile rooms, AISI 316L stainless steel is used, paying utmost care to finishing, according to GMP regulations.

The RLS fully-automatic machine can be equipped with systems to work with stoppers, caps and cover-caps simultaneously.The operator can adjust most of the machine functions from the control panel.